Process stability monitoring is the cornerstone of operational excellence, enabling organizations to maintain consistent output, reduce variability, and achieve superior quality standards in today’s competitive landscape.

🎯 The Foundation of Process Stability: Why It Matters

In manufacturing, healthcare, software development, and service industries, process stability represents the ability to maintain predictable, consistent performance over time. Without effective monitoring systems, organizations face unpredictable outcomes, increased waste, customer dissatisfaction, and compromised profitability. Understanding and implementing robust process stability monitoring transforms reactive firefighting into proactive control.

The business impact of unstable processes extends far beyond immediate production concerns. Organizations struggling with process variability experience higher costs, extended lead times, quality defects, and diminished customer trust. Conversely, companies that master stability monitoring gain competitive advantages through reliable delivery, reduced rework, improved resource utilization, and enhanced reputation.

📊 Understanding Process Variation and Control Limits

Every process exhibits variation, which falls into two distinct categories: common cause variation and special cause variation. Common cause variation represents the inherent randomness within a stable system, resulting from numerous small factors that are always present. Special cause variation stems from specific, identifiable factors that disrupt normal operations and require investigation and corrective action.

Distinguishing between these variation types is critical for effective decision-making. Treating common cause variation as if it were special cause leads to tampering, which paradoxically increases overall variation. Conversely, ignoring special cause variation allows problems to persist and compound.

Establishing Meaningful Control Limits

Control limits define the boundaries of expected process behavior based on actual performance data, not specifications or desired targets. These statistical boundaries, typically set at three standard deviations from the process mean, capture approximately 99.73% of data points when the process operates in a stable, predictable manner.

Control limits differ fundamentally from specification limits. Specifications represent customer requirements or engineering tolerances, while control limits reflect the voice of the process itself. A process may be statistically stable yet fail to meet specifications, signaling the need for process improvement rather than increased monitoring.

🔍 Statistical Process Control: The Primary Monitoring Tool

Statistical Process Control (SPC) provides the mathematical framework and visual tools for monitoring process stability. SPC charts transform raw data into actionable insights, revealing patterns, trends, and anomalies that indicate process changes requiring attention.

The most commonly used SPC charts include:

- X-bar and R charts: Monitor process mean and range for continuous data from subgroups

- Individual and Moving Range (I-MR) charts: Track individual measurements when subgrouping is impractical

- p-charts and np-charts: Monitor proportion or number of defective items in attribute data

- c-charts and u-charts: Track count of defects per unit or standardized defect density

Interpreting Control Chart Patterns

Effective process stability monitoring requires understanding specific patterns that indicate loss of control. These signal events, known as Western Electric Rules or Nelson Rules, include points beyond control limits, runs of consecutive points on one side of the centerline, trends showing seven or more consecutive ascending or descending points, and unusual patterns suggesting systematic variation.

Each pattern type suggests different underlying causes. Points beyond control limits typically indicate sudden, dramatic changes. Runs suggest process shifts or measurement bias. Trends may reflect tool wear, operator fatigue, or environmental changes. Cyclical patterns often relate to shift changes, maintenance schedules, or raw material rotation.

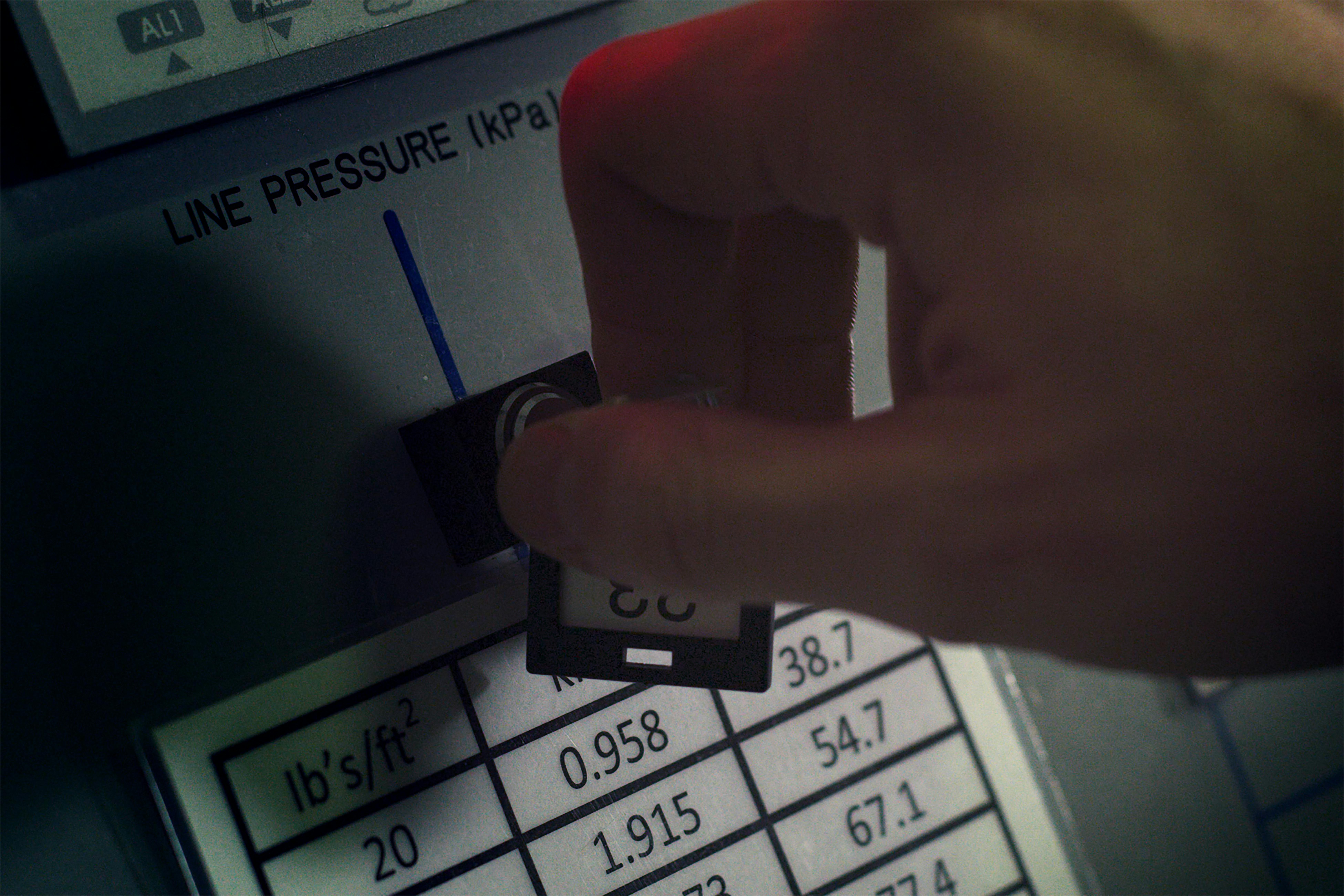

⚙️ Implementing Real-Time Monitoring Systems

Modern process stability monitoring increasingly relies on automated data collection and real-time analysis. Digital systems capture process data continuously, calculate statistical parameters automatically, and alert operators immediately when control violations occur.

Real-time monitoring systems offer several advantages over manual charting approaches. They eliminate transcription errors, provide instant feedback enabling rapid response, generate comprehensive historical databases for analysis, and scale easily across multiple processes and locations.

Selecting Appropriate Measurement Frequencies

Determining optimal measurement frequency balances the need for timely detection against resource constraints and measurement costs. High-risk processes with rapid variation require frequent sampling, while slow-moving processes with high stability may require less intensive monitoring.

The economic control chart concept helps optimize sampling strategies by balancing the costs of sampling, investigation, and process disruption against the benefits of early problem detection. Organizations should increase monitoring frequency during process changes, new product introductions, or periods following recent instability.

📈 Calculating Process Capability: Beyond Stability

While stability monitoring reveals whether a process operates predictably, capability analysis assesses whether that predictable performance meets customer requirements. Process capability indices quantify the relationship between process variation and specification limits.

Common capability indices include:

| Index | Calculation | Interpretation |

|---|---|---|

| Cp | (USL – LSL) / 6σ | Potential capability assuming perfect centering |

| Cpk | Min[(USL – μ) / 3σ, (μ – LSL) / 3σ] | Actual capability accounting for centering |

| Pp | (USL – LSL) / 6s | Overall performance using total standard deviation |

| Ppk | Min[(USL – μ) / 3s, (μ – LSL) / 3s] | Actual performance with centering adjustment |

Capability indices should only be calculated after confirming process stability. Calculating capability for unstable processes produces misleading results because the underlying statistical assumptions are violated. The sequence must always be: first achieve stability, then assess and improve capability.

🛠️ Practical Steps for Establishing Monitoring Programs

Successful process stability monitoring programs follow structured implementation approaches that ensure sustainability and organizational adoption. These programs require more than statistical knowledge—they demand change management, training, and continuous leadership support.

Phase One: Process Selection and Characterization

Begin by identifying critical processes that significantly impact quality, cost, delivery, or safety. Prioritize processes with high variation, customer complaints, or strategic importance. Document current process understanding including inputs, outputs, key process parameters, and measurement systems.

Conduct measurement system analysis to ensure data quality. Measurement systems must demonstrate adequate resolution, repeatability, and reproducibility before serving as the foundation for stability monitoring. Poor measurement systems mask true process variation or create artificial signals.

Phase Two: Baseline Data Collection and Analysis

Collect sufficient baseline data to establish initial control limits. Generally, 20-25 subgroups of consecutive production data provide adequate statistical power for initial limits. Ensure data collection occurs during representative operating conditions without deliberate interventions.

Calculate trial control limits and identify any out-of-control points or patterns. Investigate and address assignable causes before finalizing limits. This baseline phase establishes the starting point for ongoing monitoring and future improvement initiatives.

Phase Three: Ongoing Monitoring and Response Protocols

Implement standardized response protocols specifying exactly who investigates signals, what documentation is required, timeframes for investigation, and approval processes for process adjustments. Clear protocols prevent both over-reaction to common cause variation and under-reaction to genuine problems.

Establish regular review cycles to recalculate control limits as processes improve or conditions change. Control limits based on outdated process performance lose relevance and effectiveness. Many organizations recalculate limits quarterly or following significant process changes.

💡 Advanced Monitoring Techniques for Complex Processes

Complex manufacturing and service processes often require sophisticated monitoring approaches beyond basic control charts. Multivariate processes with correlated quality characteristics, batch processes with within-batch and between-batch variation, and processes with autocorrelated data demand specialized techniques.

Multivariate Statistical Process Control

When monitoring multiple correlated quality characteristics simultaneously, multivariate control charts like Hotelling’s T² and multivariate exponentially weighted moving average (MEWMA) charts provide more sensitive detection than monitoring individual characteristics separately.

These techniques account for correlation structure, reducing false alarms while improving detection of subtle multivariate shifts. However, they require larger sample sizes, more complex calculations, and careful interpretation to identify which variables contribute to out-of-control signals.

Adaptive Control Limits and Time-Weighted Charts

Traditional Shewhart charts excel at detecting large, sudden shifts but perform poorly for small, gradual changes. Exponentially weighted moving average (EWMA) and cumulative sum (CUSUM) charts provide enhanced sensitivity to small shifts by incorporating historical information.

These time-weighted approaches prove particularly valuable for critical processes where small deviations significantly impact quality or for processes where improvement efforts target incremental reduction of variation.

🎓 Building Organizational Capability and Culture

Technical tools alone cannot ensure successful process stability monitoring. Organizations must develop statistical thinking throughout the workforce and embed monitoring into daily management systems.

Effective training programs teach not just chart construction but the underlying philosophy of variation management. Operators, engineers, and managers need different depths of knowledge, but all benefit from understanding the distinction between common and special cause variation and the dangers of tampering.

Leadership’s Role in Sustaining Monitoring Systems

Leadership commitment determines whether monitoring programs thrive or atrophy. Leaders must allocate resources for training and system implementation, include stability metrics in performance reviews, participate in control chart reviews, and resist pressure to adjust stable processes based on individual data points.

When leaders understand and respect the principles of process stability monitoring, they create environments where data-driven decision making flourishes. When leaders bypass or undermine monitoring systems, they signal that the tools are bureaucratic requirements rather than strategic assets.

🚀 Leveraging Stability for Continuous Improvement

Process stability monitoring serves two complementary purposes: maintaining current performance and enabling systematic improvement. Stable processes provide the foundation for experimental learning and capability enhancement.

Once stability is achieved, improvement teams can confidently implement changes and evaluate results. The stable baseline enables clear attribution of observed changes to specific interventions rather than random variation. This accelerates learning cycles and prevents wasted effort on ineffective countermeasures.

Integrating Monitoring with Problem-Solving Methodologies

Process stability monitoring integrates naturally with structured improvement methodologies including Six Sigma, Lean, and Plan-Do-Check-Act cycles. Control charts provide the “check” component, revealing whether changes produced intended results and whether improvements are sustained over time.

Advanced organizations embed control charts throughout improvement projects: establishing baseline capability, monitoring implementation phases for unintended consequences, verifying improvement effectiveness, and ensuring long-term sustainability through ongoing monitoring.

🌟 Measuring and Communicating Program Success

Demonstrating the business value of process stability monitoring programs ensures continued investment and organizational support. Effective metrics quantify both process health and business outcomes.

Process health metrics include percentage of processes in statistical control, time to detect and resolve out-of-control conditions, and rate of special cause identification and elimination. Business outcome metrics connect stability to financial performance through reduced scrap and rework costs, improved on-time delivery rates, decreased customer complaints, and enhanced throughput.

Creating Compelling Visual Management Systems

Visual management brings process stability information to the gemba where value is created. Production boards displaying current control charts, trending performance metrics, and improvement initiatives make process health visible and actionable.

Effective visual systems use color coding for immediate status recognition, display both short-term performance and long-term trends, highlight improvement opportunities, and celebrate stability achievements. These systems democratize data access and engage frontline workers in continuous improvement.

🔮 Future Trends in Process Stability Monitoring

Emerging technologies are transforming process stability monitoring capabilities. Artificial intelligence and machine learning algorithms detect subtle patterns human analysts might miss, predict impending process shifts before they occur, and optimize sampling strategies dynamically based on process conditions.

Internet of Things (IoT) sensors enable unprecedented data density, capturing process parameters continuously rather than through periodic sampling. This data richness enables earlier problem detection and deeper process understanding but also requires sophisticated data management and analysis infrastructure.

Cloud-based monitoring platforms facilitate enterprise-wide visibility, enabling centralized experts to support multiple locations, standardizing methods across facilities, and aggregating insights from similar processes across the organization. These platforms democratize advanced statistical capabilities while ensuring methodological consistency.

🎯 Taking Action: Your Stability Monitoring Roadmap

Organizations beginning their process stability monitoring journey should start small, prove value, and expand systematically. Select one or two critical processes as pilots, ensuring they have adequate measurement systems and leadership support. Achieve demonstrable success before expanding to additional processes.

Invest in education before implementation. Statistical process control works best when understood broadly rather than practiced by specialists in isolation. Build capability throughout operations, quality, engineering, and management to create sustainable systems.

Remember that process stability monitoring is not a destination but a journey. Even mature programs continuously refine their approaches, adopt new techniques, and expand applications. The discipline of monitoring creates competitive advantages that compound over time through incremental improvements and organizational learning.

Organizations that master process stability monitoring unlock remarkable benefits: consistent quality that builds customer loyalty, operational efficiency that enhances profitability, and the foundation for continuous improvement that sustains competitive advantage. The journey requires commitment, but the destination—operational excellence—justifies the investment many times over.

Toni Santos is a production systems researcher and industrial quality analyst specializing in the study of empirical control methods, production scaling limits, quality variance management, and trade value implications. Through a data-driven and process-focused lens, Toni investigates how manufacturing operations encode efficiency, consistency, and economic value into production systems — across industries, supply chains, and global markets. His work is grounded in a fascination with production systems not only as operational frameworks, but as carriers of measurable performance. From empirical control methods to scaling constraints and variance tracking protocols, Toni uncovers the analytical and systematic tools through which industries maintain their relationship with output optimization and reliability. With a background in process analytics and production systems evaluation, Toni blends quantitative analysis with operational research to reveal how manufacturers balance capacity, maintain standards, and optimize economic outcomes. As the creative mind behind Nuvtrox, Toni curates production frameworks, scaling assessments, and quality interpretations that examine the critical relationships between throughput capacity, variance control, and commercial viability. His work is a tribute to: The measurement precision of Empirical Control Methods and Testing The capacity constraints of Production Scaling Limits and Thresholds The consistency challenges of Quality Variance and Deviation The commercial implications of Trade Value and Market Position Analysis Whether you're a production engineer, quality systems analyst, or strategic operations planner, Toni invites you to explore the measurable foundations of manufacturing excellence — one metric, one constraint, one optimization at a time.