Feedback-driven process control transforms how organizations achieve operational excellence, enabling precision, adaptability, and continuous improvement across every business function.

🎯 The Foundation of Feedback-Driven Process Control

In today’s competitive landscape, organizations can no longer rely on static processes and hope for optimal results. Feedback-driven process control represents a paradigm shift in operational management, where real-time data, continuous monitoring, and systematic adjustments create a self-optimizing system. This approach fundamentally changes how businesses respond to variations, inefficiencies, and opportunities for improvement.

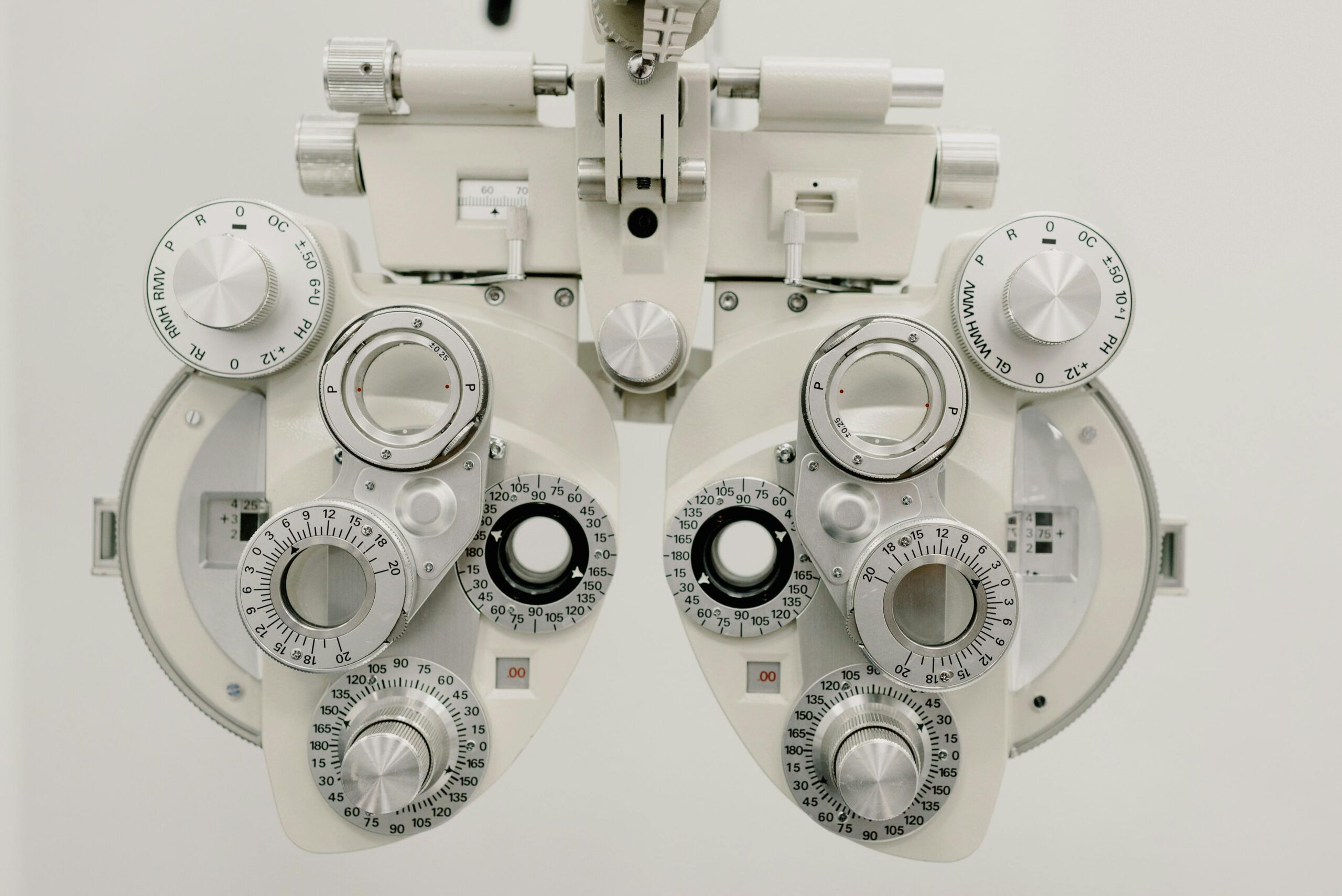

The concept draws inspiration from engineering control systems, where sensors continuously measure output, compare it against desired targets, and automatically adjust inputs to maintain optimal performance. When applied to business operations, this methodology creates intelligent processes that learn, adapt, and improve autonomously while keeping human decision-makers informed and in control.

Traditional process management often operates in a reactive mode, where problems are identified only after they’ve caused damage. Feedback-driven control flips this model entirely, creating proactive systems that detect deviations before they become critical issues. This fundamental difference separates organizations that merely survive from those that consistently outperform their competitors.

Understanding the Feedback Loop Architecture

Every effective feedback-driven system relies on four essential components working in harmony. The measurement phase captures relevant performance indicators through sensors, data collection tools, or observation mechanisms. These measurements must be accurate, timely, and representative of the process outcomes you’re attempting to optimize.

The comparison phase evaluates current performance against established benchmarks, targets, or historical standards. This analysis identifies gaps between actual and desired performance, quantifying the magnitude and urgency of any deviations. Without clear comparison criteria, feedback becomes noise rather than actionable intelligence.

The decision phase determines appropriate corrective actions based on the identified gaps. This stage may involve automated responses for routine deviations or human judgment for complex situations requiring contextual understanding. The sophistication of this decision-making process directly impacts system effectiveness.

Finally, the implementation phase executes chosen adjustments, modifying process inputs, methods, or resources to bring performance back toward target levels. The cycle then repeats continuously, creating a dynamic system that responds to changing conditions in real-time.

🔍 Identifying Critical Control Points in Your Operations

Not every aspect of your operations requires the same level of feedback-driven control. Strategic identification of critical control points maximizes return on investment while avoiding analysis paralysis. These control points typically share common characteristics: they significantly impact customer value, represent high-cost activities, frequently exhibit variation, or create bottlenecks in your workflow.

Manufacturing environments often focus control efforts on quality checkpoints, machine performance metrics, and material flow rates. Service organizations might prioritize customer interaction quality, response times, and resolution rates. Knowledge work benefits from tracking decision cycle times, collaboration effectiveness, and output quality metrics.

The key lies in distinguishing between leading and lagging indicators. Lagging indicators tell you what has already happened—useful for learning but less valuable for prevention. Leading indicators predict future performance, enabling preemptive action before problems materialize. A balanced dashboard incorporates both types, creating comprehensive visibility.

Designing Measurement Systems That Actually Work

Measurement systems form the sensory network of feedback-driven control, yet many organizations struggle with data collection that’s either too sparse to be useful or so overwhelming it paralyzes decision-making. Effective measurement balances comprehensiveness with practicality, capturing essential information without creating burdensome overhead.

Automation plays a crucial role in modern measurement systems. Digital sensors, IoT devices, and software monitoring tools can capture vast quantities of data without human intervention, ensuring consistency and timeliness. However, certain qualitative aspects still require human assessment, particularly those involving subjective experience or complex judgment.

Consider these measurement system design principles:

- Measurements should be objective and reproducible across different observers or conditions

- Collection frequency must match the pace of process variation and required response times

- Data granularity should enable root cause analysis without unnecessary complexity

- Measurement costs must remain proportionate to the value of improved control

- Systems should minimize disruption to the processes being measured

⚙️ Setting Performance Standards and Target Ranges

Feedback mechanisms require clear targets to function effectively, yet establishing appropriate performance standards challenges many organizations. Targets set too aggressively create constant alarm fatigue, while overly conservative standards mask opportunities for improvement. The optimal approach balances aspiration with achievability.

Statistical process control offers valuable frameworks for establishing target ranges. Rather than single-point targets, control limits define acceptable variation boundaries. Performance within these limits indicates a stable, predictable process, while excursions beyond them signal special causes requiring investigation and correction.

Benchmarking provides external reference points, revealing what’s possible when you study best-in-class performers. However, blindly adopting external benchmarks without considering your specific context, resources, and strategic priorities often leads to misalignment. The most effective standards combine external insights with internal capabilities and improvement trajectories.

Dynamic standards that evolve as capabilities improve create continuous improvement momentum. As teams consistently achieve current targets, gradually tightening standards maintains challenge and prevents complacency. This approach, fundamental to methodologies like Kaizen, ensures feedback-driven control supports ongoing advancement rather than mere maintenance of status quo.

Building Responsive Feedback Mechanisms

The speed and effectiveness of your response mechanisms determine whether feedback-driven control delivers theoretical or practical value. Response design must consider both the urgency of different deviation types and the organizational capacity to implement corrections without creating chaos or resistance.

Automated responses suit repetitive, well-understood situations where appropriate corrective actions are clear. Manufacturing processes often employ automated adjustments to machine parameters when sensor data indicates drift. Digital marketing campaigns can automatically reallocate budget toward higher-performing channels based on conversion data.

Human-in-the-loop responses work better for situations requiring contextual judgment, creativity, or ethical consideration. These hybrid systems present decision-makers with analysis and recommendations while reserving final authority for human judgment. This approach balances efficiency with wisdom, preventing automated systems from optimizing toward unintended or harmful outcomes.

Response escalation protocols ensure appropriate attention levels match deviation severity. Minor variations might trigger automatic adjustments or operator notifications, while significant deviations escalate to supervisors or management. Critical situations activate emergency response procedures with cross-functional coordination.

📊 Leveraging Technology for Process Intelligence

Modern technology dramatically expands the possibilities for feedback-driven control, enabling sophistication that was previously impossible or prohibitively expensive. Cloud computing provides scalable infrastructure for collecting, storing, and analyzing massive datasets. Edge computing processes data closer to sources, enabling real-time responses with minimal latency.

Artificial intelligence and machine learning algorithms can identify patterns humans might miss, predict future performance based on historical trends, and recommend optimal adjustments for complex situations with multiple interacting variables. These technologies excel at handling high-dimensional problems where traditional analytical approaches become unwieldy.

Digital twin technology creates virtual replicas of physical processes, allowing organizations to simulate different scenarios and test potential adjustments before implementing them in the real world. This capability reduces risk while accelerating learning and innovation. Industries from aerospace to healthcare increasingly rely on digital twins for process optimization.

Integration platforms connect disparate systems, ensuring feedback loops span organizational boundaries rather than creating siloed optimization that suboptimizes overall performance. When purchasing, production, quality control, and delivery systems share information seamlessly, the entire value chain becomes responsive and coordinated.

Creating a Culture That Embraces Feedback

Technology and methodology mean little without organizational culture that embraces feedback as a gift rather than criticism. Many improvement initiatives fail not from technical deficiencies but from human resistance rooted in fear, pride, or misaligned incentives. Cultural transformation often determines success or failure more than any other factor.

Psychological safety forms the foundation of feedback-receptive cultures. Team members must believe they can report problems, admit mistakes, and suggest improvements without fear of punishment or ridicule. Leaders model this behavior by openly acknowledging their own errors and welcoming challenging perspectives.

Separating performance feedback from personal worth prevents defensive reactions that block learning. Effective feedback cultures frame deviations as process issues requiring systematic resolution rather than individual failures demanding blame. This distinction liberates people to engage honestly with performance data.

Recognition and reward systems must align with feedback-driven improvement rather than contradicting it. When organizations claim to value learning and adaptation while only rewarding short-term results or perfect execution, people rationally prioritize what’s rewarded over what’s espoused. Authentic cultural change requires consistent alignment between stated values and actual incentives.

🚀 Implementing Feedback Control Across Different Functions

While principles remain consistent, effective implementation varies significantly across different organizational functions. Manufacturing operations might focus on equipment efficiency, defect rates, and throughput metrics. Quality management systems track conformance to specifications, customer complaints, and corrective action effectiveness.

Sales and marketing functions benefit from feedback on lead quality, conversion rates, customer acquisition costs, and campaign performance. Real-time dashboards enable rapid reallocation of resources toward high-performing channels or messages. Customer lifetime value metrics provide longer-term feedback on relationship quality beyond initial transactions.

Human resources can apply feedback-driven control to recruitment effectiveness, onboarding success, employee engagement, and turnover prediction. Regular pulse surveys provide leading indicators of cultural health, enabling proactive intervention before problems escalate to departures or productivity losses.

Financial operations track cash flow, budget variance, forecasting accuracy, and compliance metrics. Automated alerts flag unusual transactions or patterns that might indicate errors or fraud. Predictive analytics anticipate cash needs, preventing shortfalls while minimizing idle capital.

Overcoming Common Implementation Challenges

Organizations frequently encounter predictable obstacles when implementing feedback-driven process control. Anticipating these challenges and preparing appropriate responses significantly improves success rates. Data quality issues rank among the most common problems—garbage in, garbage out remains as true as ever. Establishing data governance standards and validation procedures addresses this fundamental requirement.

Analysis paralysis occurs when organizations collect excessive data without clear prioritization or decision frameworks. The solution lies in distinguishing between nice-to-know and need-to-know information, focusing measurement efforts on truly critical indicators, and establishing clear decision rules that prevent endless deliberation.

Change fatigue emerges when constant adjustments overwhelm people’s capacity to adapt. Effective implementation balances responsiveness with stability, changing only what requires changing when it requires changing. Not every deviation demands immediate correction—some represent normal variation within acceptable ranges.

Siloed optimization creates local improvements that harm overall system performance. A manufacturing department that optimizes its throughput by building excess inventory may inadvertently increase working capital requirements and obsolescence risk. Cross-functional governance and end-to-end process ownership mitigate this risk.

🎓 Advanced Techniques for Continuous Improvement

Once basic feedback-driven control mechanisms are functioning reliably, organizations can explore advanced techniques that deliver additional performance gains. Statistical process control employs control charts and capability analysis to distinguish common cause from special cause variation, focusing improvement efforts where they’ll deliver maximum impact.

Design of experiments methodology systematically varies multiple process parameters simultaneously to identify optimal configurations. This approach proves particularly valuable for complex processes with many interacting variables where intuitive trial-and-error becomes inefficient or misleading.

Predictive maintenance uses equipment performance data, environmental conditions, and usage patterns to forecast when failures are likely to occur. This enables preventive interventions at optimal times—avoiding both premature replacement and unexpected breakdowns. Industries with expensive capital equipment realize substantial value from these capabilities.

Adaptive control systems automatically adjust their own control parameters based on changing conditions or learning from past performance. These self-tuning systems maintain optimal performance across varying operating conditions without constant human intervention, representing the leading edge of intelligent automation.

Measuring the Impact of Feedback-Driven Control

Demonstrating value from feedback-driven process control requires thoughtful impact measurement that captures both quantitative benefits and qualitative improvements. Financial metrics might include reduced waste, lower defect costs, decreased inventory carrying costs, or improved asset utilization rates. These hard numbers typically resonate with executive stakeholders and financial decision-makers.

Operational metrics reveal improvements in cycle times, throughput rates, first-pass yield, or capacity utilization. These indicators directly reflect enhanced process capability and efficiency. Comparing before-and-after performance provides compelling evidence of system effectiveness.

Customer impact metrics such as satisfaction scores, Net Promoter Scores, complaint rates, or retention percentages demonstrate external value creation. After all, operational excellence that doesn’t translate to improved customer experience misses the ultimate purpose of business operations.

Employee experience metrics including engagement scores, turnover rates, and innovation suggestions indicate whether feedback-driven control enhances or burdens your workforce. Sustainable improvement requires systems that empower rather than overwhelm people, making work more satisfying while delivering better results.

💡 Future Trends Shaping Process Control Evolution

The trajectory of feedback-driven process control points toward increasingly intelligent, autonomous, and predictive systems. Artificial intelligence capabilities continue advancing rapidly, enabling systems that not only respond to deviations but anticipate them before they occur. Predictive algorithms will become standard rather than exceptional.

Internet of Things proliferation places sensors and connectivity everywhere, dramatically expanding the scope and granularity of measurable phenomena. This data abundance creates new opportunities while demanding more sophisticated approaches to information management and analysis. Organizations will compete based on their ability to extract insight from data noise.

Augmented reality interfaces will transform how humans interact with feedback systems, overlaying performance data onto physical environments in intuitive, actionable formats. Technicians will see equipment health indicators while looking at machines, while managers will view departmental performance metrics as they walk through facilities.

Blockchain and distributed ledger technologies may enable secure, transparent feedback loops across organizational boundaries, creating trustworthy supply chain visibility and enabling collaborative optimization among partners who share goals but not systems. This could transform industries with complex, multi-party value chains.

Building Your Feedback-Driven Transformation Roadmap

Successful transformation toward feedback-driven operations requires thoughtful planning and phased implementation rather than attempting overnight revolution. Begin by identifying one or two high-impact processes where improvement would deliver significant value and success appears achievable with available resources and capabilities.

Establish baseline performance measurements before implementing changes, creating clear reference points for demonstrating improvement. Document current process flows, identify pain points, and engage frontline workers who understand practical realities often invisible from management perspectives. Their insights prove invaluable for designing systems that actually work in practice.

Pilot your feedback control systems in limited scope before enterprise-wide rollout. This approach allows learning and refinement in a controlled environment where mistakes won’t create catastrophic consequences. Successful pilots generate credibility and momentum while revealing unexpected challenges that deserve attention before broader implementation.

Scale systematically based on lessons learned and demonstrated results. As capabilities mature and confidence grows, expand feedback-driven control to additional processes and functions. Maintain discipline around change management, ensuring each expansion includes proper training, clear accountability, and adequate support resources.

Building organizational mastery through feedback-driven process control represents a journey rather than a destination. Markets evolve, technologies advance, and competitive pressures intensify. Organizations that embed continuous learning and adaptation into their operational DNA maintain relevance and performance regardless of external changes. The principles and practices outlined here provide a foundation for creating intelligent, responsive operations that consistently deliver superior results through precision, insight, and systematic improvement.

Toni Santos is a production systems researcher and industrial quality analyst specializing in the study of empirical control methods, production scaling limits, quality variance management, and trade value implications. Through a data-driven and process-focused lens, Toni investigates how manufacturing operations encode efficiency, consistency, and economic value into production systems — across industries, supply chains, and global markets. His work is grounded in a fascination with production systems not only as operational frameworks, but as carriers of measurable performance. From empirical control methods to scaling constraints and variance tracking protocols, Toni uncovers the analytical and systematic tools through which industries maintain their relationship with output optimization and reliability. With a background in process analytics and production systems evaluation, Toni blends quantitative analysis with operational research to reveal how manufacturers balance capacity, maintain standards, and optimize economic outcomes. As the creative mind behind Nuvtrox, Toni curates production frameworks, scaling assessments, and quality interpretations that examine the critical relationships between throughput capacity, variance control, and commercial viability. His work is a tribute to: The measurement precision of Empirical Control Methods and Testing The capacity constraints of Production Scaling Limits and Thresholds The consistency challenges of Quality Variance and Deviation The commercial implications of Trade Value and Market Position Analysis Whether you're a production engineer, quality systems analyst, or strategic operations planner, Toni invites you to explore the measurable foundations of manufacturing excellence — one metric, one constraint, one optimization at a time.